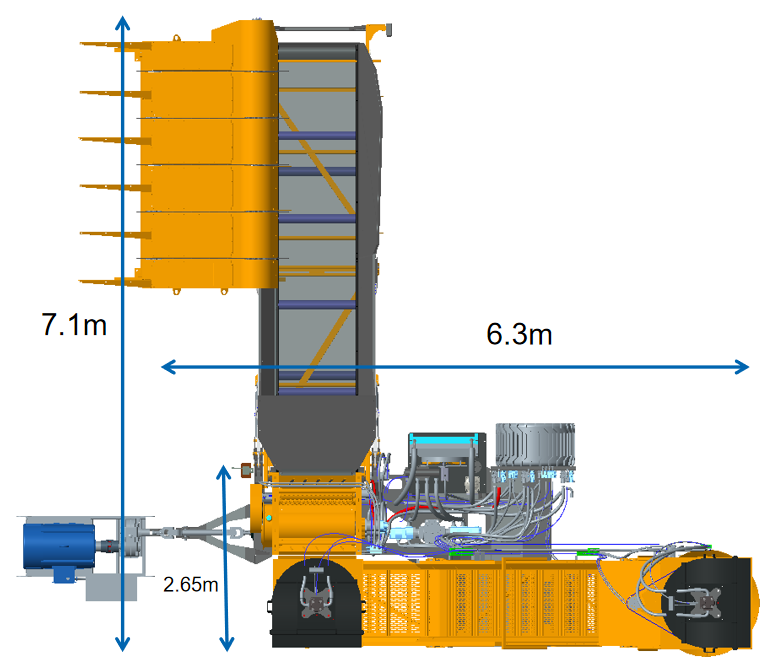

6CZQ-20

Redefine Mechanized Sugarcane Harvesting, Bringing the Benefits ofSugarcane Mechanization to Every Inch of Land

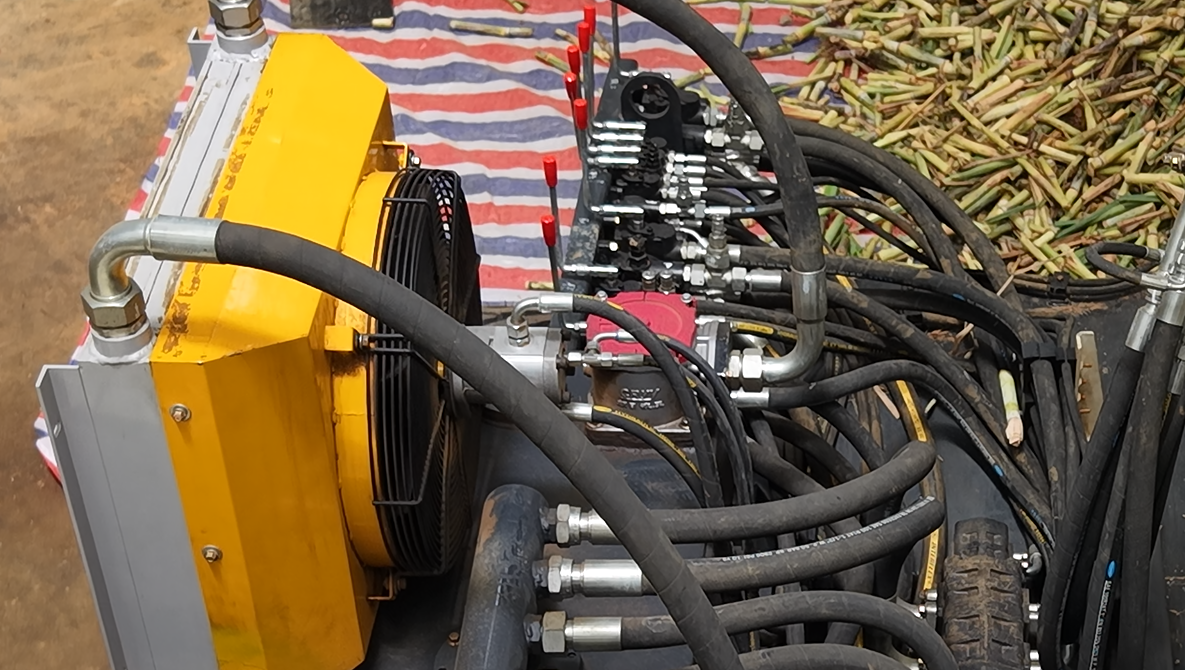

Core Advantage of Our Sugarcane Impurity Removal Equipment: Full Hydraulic Drive for the Entire Machine

Our sugarcane impurity removal equipment features full hydraulic drive for the entire machine as its core technical highlight.

1. Flexible Multi-Power Adaptation, Seamlessly Meeting Oil & Electric Needs

Equipped with a full hydraulic transmission system, the equipment delivers strong power. It can be driven either by the PTO (Power Take-Off) of a tractor or powered by an electric system — providing dual flexibility to match different on-site power conditions.

2. Upgraded Simplified Structure, Less Maintenance & Higher Reliability

The full hydraulic drive design reduces the number of moving parts, significantly lowering the risk of malfunctions. Even during the intensive sugarcane processing season with long operating hours and heavy loads, the equipment maintains stable operation. This not only effectively extends its service life but also reduces the overall operating costs for enterprises.

3. 3X Cutting & Impurity Removal Capacity, Far Surpassing Pure Electric Drive

Addressing the need for efficient cutting and impurity removal of thick sugarcane stalks, the core cutting channel of the equipment is exclusively driven by an adaptive parallel hydraulic system. Leveraging the high torque advantage of hydraulic transmission, its cutting and impurity removal capacity is 3 times higher than that of pure electric-driven solutions. It can quickly cut sugarcane stalks and separate impurities such as leaves and soil, preventing material blockages. When handling large volumes of sugarcane, there is no need for repeated shutdowns for cleaning, which greatly improves impurity removal throughput and easily copes with the processing pressure during the peak harvest season